Ergonomics simulation is transforming the way organizations address workplace risk factors, leading to safer and more efficient environments. By virtually modeling human interactions with tasks, tools, and workspaces, companies can identify potential hazards and implement solutions before they become real-world problems. This article provides a comprehensive exploration of ergonomics simulation, including its definition, benefits, key features, and practical examples.

What Is Ergonomics Simulation in Workplace Safety?

Ergonomics simulation in workplace safety is the use of virtual modeling and computational tools to analyze and optimize the interaction between workers and their environment. It aims to design tasks, workspaces, and systems that fit the user’s physical capabilities and limitations, thereby reducing the risk of injuries and enhancing productivity.

The reason ergonomics simulation is vital is that it allows for proactive identification of potential ergonomic issues. For example, by simulating the lifting tasks in a warehouse, companies can redesign processes to minimize strain on workers’ backs, reducing the incidence of musculoskeletal disorders.

Why Are Workplace Risk Factors Important to Address?

Workplace risk factors are conditions or practices that increase the likelihood of injuries or illnesses among employees. Addressing these factors is crucial because they directly impact employee health, company productivity, and financial costs.

Key workplace risk factors include:

- Repetitive Motions: Performing the same movement repeatedly can lead to strain injuries.

- Awkward Postures: Positions that put stress on the body, such as twisting or bending, increase injury risk.

- Forceful Exertions: Tasks requiring significant physical effort can cause fatigue and harm.

- Vibration Exposure: Operating vibrating tools may lead to circulation and nerve problems.

- Environmental Conditions: Poor lighting, extreme temperatures, and noise can affect safety and comfort.

For example, in 2020, the U.S. Bureau of Labor Statistics reported over 266,000 cases of musculoskeletal disorders, many resulting from these risk factors. By addressing them through ergonomics simulation, companies can prevent such incidents.

How Does Ergonomics Simulation Help Mitigate Workplace Risk Factors?

Ergonomics simulation helps mitigate workplace risk factors by allowing organizations to model and analyze work processes in a virtual environment. This approach enables the identification of potential hazards and the testing of interventions without disrupting actual operations.

The process involves:

- Modeling Tasks and Workspaces: Creating virtual replicas of the workplace and tasks.

- Analyzing Human Movements: Using digital human models to assess postures and movements.

- Identifying Hazards: Detecting areas where risk factors are present.

- Testing Solutions: Simulating changes to evaluate their effectiveness.

For instance, Descar.Tech utilizes Siemens PLM software to simulate production lines, identifying bottlenecks and ergonomic issues. By adjusting the layout virtually, they can recommend design changes that enhance safety and efficiency.

What Are the Main Benefits of Using Ergonomics Simulation?

The main benefits of using ergonomics simulation include:

- Injury Reduction: Decreasing the incidence of work-related injuries by identifying risks early.

- Cost Savings: Lowering costs associated with healthcare, compensation, and lost productivity.

- Productivity Improvement: Enhancing efficiency by designing tasks that align with human capabilities.

- Regulatory Compliance: Meeting safety standards set by organizations like OSHA.

- Employee Satisfaction: Increasing morale by providing a safer and more comfortable work environment.

A real-world example is a manufacturing company that implemented ergonomics simulation and saw a 25% reduction in injury-related absenteeism within a year.

Which Industries Can Benefit from Ergonomics Simulation?

Various industries can benefit from ergonomics simulation, including:

- Manufacturing: Optimizing assembly lines to reduce repetitive strain.

- Healthcare: Designing equipment and workflows that minimize caregiver fatigue.

- Construction: Planning tasks to prevent overexertion and falls.

- Logistics: Streamlining warehouse operations for safer material handling.

- Automotive: Improving vehicle assembly processes to enhance worker safety.

For example, in the automotive industry, ergonomics simulation can adjust the height of assembly stations to suit workers’ heights, reducing awkward postures.

How Does Descar.Tech Specialize in Ergonomics Simulation?

Descar.Tech is a company specializing in the design and simulation of industrial processes, focusing on optimizing production through technological innovation. Their expertise in ergonomics simulation includes:

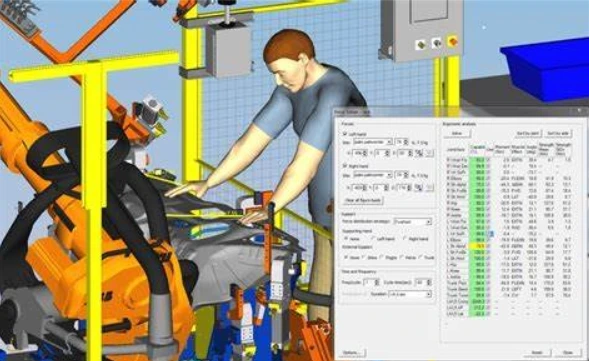

- Virtual Modeling: Creating detailed simulations of production lines using Siemens PLM tools.

- Risk Assessment: Identifying ergonomic risks in tasks and workflows.

- Process Optimization: Recommending design changes to enhance safety and efficiency.

- Automation Integration: Implementing robotic solutions to reduce human risk factors.

By offering comprehensive solutions ranging from machine design to process automation, Descar.Tech helps clients increase efficiency, decrease risks, reduce costs and improve project quality.

What Are Key Features of Ergonomics Simulation Tools?

Key features of ergonomics simulation tools include:

- Digital Human Modeling: Creating virtual representations of workers to analyze movements.

- Task Analysis: Evaluating specific tasks for ergonomic risks.

- Posture Assessment: Measuring joint angles and body positions.

- Force Analysis: Calculating the physical forces required for tasks.

- Environmental Simulation: Incorporating factors like lighting and noise.

For instance, Siemens Process Simulate PLM software allows for detailed human modeling, enabling precise assessments of how a worker interacts with equipment.

How Does Ergonomics Simulation Support Design for Manufacturing?

Ergonomics simulation supports design for manufacturing by ensuring that products and processes are designed with human capabilities in mind. This integration leads to:

- Improved Assembly Processes: Designing products that are easier and safer to assemble.

- Reduced Errors: Minimizing the likelihood of mistakes caused by complex tasks.

- Enhanced Collaboration: Facilitating communication between designers and production teams.

For more on this topic, visit Descar.Tech’s article on Design for Manufacturing.

What Is the Role of Ergonomics Simulation in Industrial Automation?

In industrial automation, ergonomics simulation plays a role in:

- Integrating Robots and Humans: Designing workflows where automation complements human tasks.

- Safety Analysis: Ensuring automated systems do not introduce new risk factors.

- Process Efficiency: Optimizing both automated and manual processes for better performance.

By simulating these interactions, companies like Descar.Tech help clients implement automation solutions that enhance safety and productivity. Learn more at Descar.Tech’s article on Industrial Automation.

How Can Ergonomics Simulation Improve Plant Simulation Modeling?

Ergonomics simulation enhances plant simulation modeling by incorporating human factors into the overall system design. This integration leads to:

- Accurate Workflow Representation: Reflecting real human interactions within the plant model.

- Risk Mitigation: Identifying potential ergonomic issues in the early stages of design.

- Optimized Layouts: Arranging equipment and workspaces for maximum efficiency and safety.

For a deeper understanding, explore Descar.Tech’s insights on Plant Simulation.

What Scientific Research Supports Ergonomics Simulation?

Scientific research supporting ergonomics simulation includes:

- A 2018 study in the Journal of Occupational and Environmental Medicine: Found that ergonomics interventions reduced musculoskeletal disorders by 59%.

- Research by the National Institute for Occupational Safety and Health (NIOSH): Demonstrated that simulation tools effectively predict ergonomic risks.

These studies validate the effectiveness of ergonomics simulation in preventing workplace injuries.

How Does Ergonomics Simulation Relate to Advanced Planning and Scheduling Systems?

Ergonomics simulation relates to Advanced Planning and Scheduling (APS) systems by:

- Aligning Human Resources with Production Plans: Ensuring that schedules consider human capabilities.

- Optimizing Task Assignments: Matching workers to tasks that suit their ergonomic profiles.

- Enhancing Flexibility: Allowing for adjustments in schedules based on ergonomic data.

For beginners interested in APS systems, refer to Descar.Tech’s overview of Key Components of APS Systems.

What Are Real-Life Examples of Ergonomics Simulation Applications?

Real-life examples include:

- Automotive Manufacturing: Companies using simulation to redesign workstations, resulting in a 30% reduction in injury rates.

- Aerospace Industry: Simulating assembly tasks to prevent overreaching and awkward postures.

- Healthcare Facilities: Modeling patient handling procedures to minimize caregiver injuries.

In 2021, a study by Applied Ergonomics showed that implementing ergonomics simulation in a manufacturing plant led to a 15% increase in productivity.

How Do Companies Begin Implementing Ergonomics Simulation?

Companies can begin implementing ergonomics simulation by:

- Assessing Current Processes: Identifying areas with high risk factors.

- Selecting Appropriate Tools: Choosing simulation software that fits their needs.

- Training Staff: Educating employees on the use of simulation tools.

- Partnering with Experts: Collaborating with specialists like Descar.Tech.

- Starting Small: Piloting simulations in specific areas before scaling up.

By taking these steps, organizations can integrate ergonomics simulation into their safety and efficiency strategies.

How Does Ergonomics Simulation Contribute to Overall Workplace Safety?

Ergonomics simulation contributes to overall workplace safety by:

- Preventing Injuries: Reducing risk factors before they cause harm.

- Enhancing Compliance: Meeting regulatory requirements for ergonomics.

- Promoting a Safety Culture: Encouraging proactive safety measures among employees.

- Improving Communication: Facilitating discussions about safety between management and staff.

By focusing on human well-being, ergonomics simulation creates a safer and more productive work environment.

Frequently Asked Questions

What Software Is Commonly Used for Ergonomics Simulation?

Common software includes Siemens PLM tools, Process Simulate Human, and Tecnomatix, which offer advanced capabilities for modeling human interactions.

Can Ergonomics Simulation Be Applied in Office Environments?

Yes, ergonomics simulation can optimize office layouts, workstation designs, and task assignments to reduce strain and enhance comfort.

How Does Ergonomics Simulation Affect Employee Morale?

By improving safety and comfort, ergonomics simulation positively impacts employee morale, leading to increased job satisfaction and retention.

Is Ergonomics Simulation Cost-Effective for Small Businesses?

While there is an initial investment, the long-term benefits of reduced injuries and increased productivity often result in cost savings, making it viable for small businesses.

How Does Descar.Tech Support Clients in Ergonomics Simulation?

Descar.Tech offers expertise in virtual modeling, risk assessment, and process optimization, helping clients implement effective ergonomics solutions.

What Is the Difference Between Ergonomics Simulation and Traditional Ergonomics Assessments?

Traditional assessments rely on observations and checklists, while ergonomics simulation uses virtual modeling to predict and prevent issues before they occur.

How Long Does It Take to See Results from Ergonomics Simulation?

Results can vary, but companies often see improvements in safety and productivity within months of implementation.

Are There Industry Standards for Ergonomics Simulation?

Standards like ISO 45001 provide guidelines for occupational health and safety management, which can be supported by ergonomics simulation practices.

Can Ergonomics Simulation Help with Remote Workstation Design?

Yes, simulation can optimize home office setups, ensuring remote workers have ergonomically sound environments.

How Does Ergonomics Simulation Integrate with Lean Manufacturing Principles?

Ergonomics simulation complements lean manufacturing by eliminating waste related to worker discomfort and inefficiency, leading to streamlined processes.For more insights into industrial process optimization and design, visit Descar.Tech’s resources. By leveraging ergonomics simulation, organizations can significantly enhance workplace safety, efficiency, and employee well-being.

Contact us

Recent Comments