A new type of simulation for industrial plant design and modeling is changing the way companies plan, build and operate their facilities. Plant simulation provides a detailed representation of the actual operation of an industrial plant, allowing engineers to identify and resolve problems before they occur.

What is industrial plant design?

Industrial plant design is a branch of engineering that is responsible for the design, construction and commissioning of industrial facilities. These facilities can be of any type, from factories and power plants to wastewater treatment plants. The objective of industrial plant design is to maximize the efficiency and safety of the facilities, in addition to minimizing production costs.

To do this, engineers must take into account all aspects of the industrial process, from the supply of raw materials to the transportation and storage of finished products. Likewise, they must also guarantee that the facilities comply with all current regulations regarding safety and the environment.

What is plant simulation?

Plant simulation is a tool used for the design and modeling of industrial plants. This is a special type of simulation that allows you to recreate the real operation of an industrial plant.

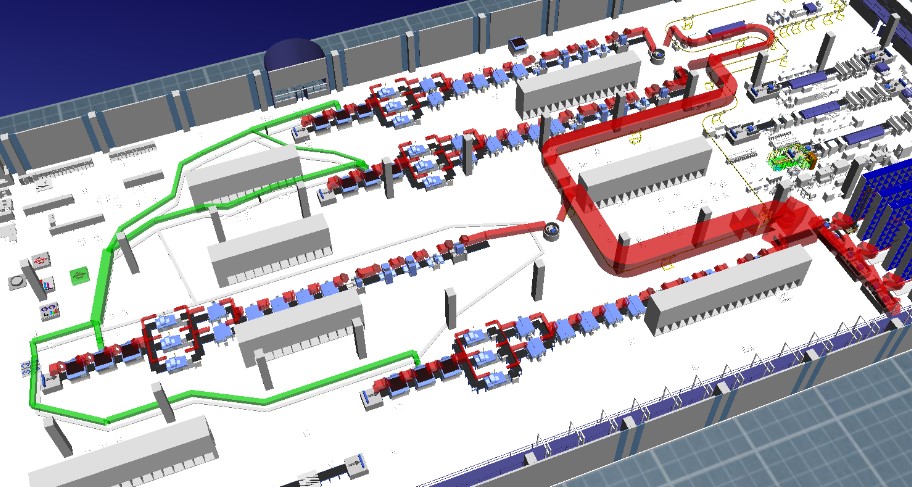

Plant simulation is based on the creation of a digital model of the installation. This model is developed from real data about the terrain, the building and the plant equipment. From this model, a series of simulations can be carried out to evaluate different operating scenarios.

Plant simulation allows engineers to identify and solve problems before they occur.

Benefits of Plant Simulation

Thanks to plant simulation (plan simulation in English), companies can plan the design and construction of their facilities more efficiently. They can also use simulation to evaluate the impact of changes to plant processes, as well as to optimize equipment use and reduce operating costs.

Plant simulation systems are changing the way industrial plants are designed and modeled. It is an invaluable tool to guarantee efficiency in the automation and manufacturing of products and the safety of facilities.

What is Tecnomatix Plant Simulation?

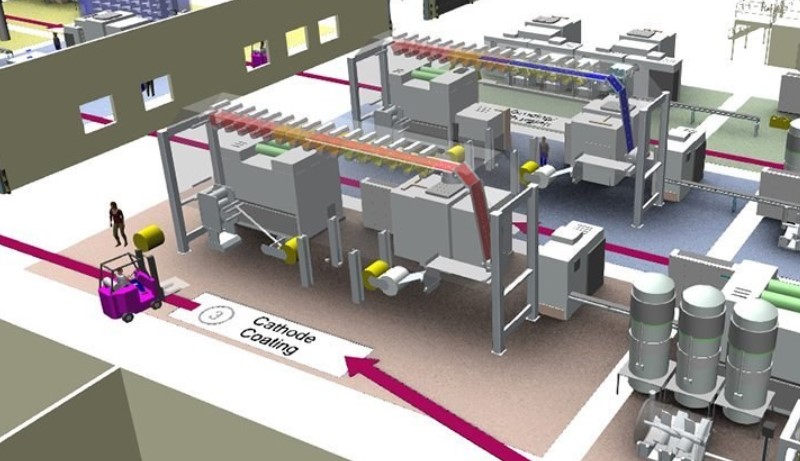

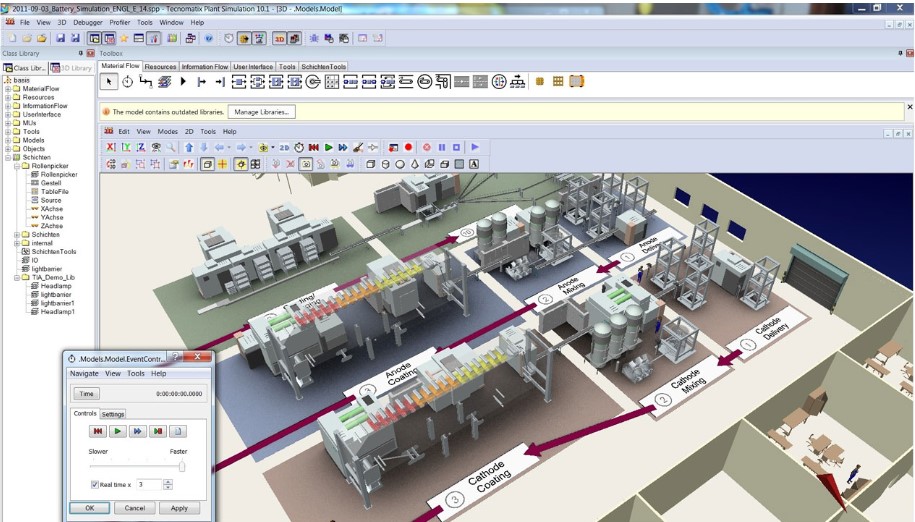

Tecnomatix Plant Simulation is a Discrete Event simulation software used for supply chain analysis and optimization. The software allows users to create workflow models and analyze the impact of design changes before implementing them.

Tecnomatix Plant Simulation can also be used for production planning and control, as well as warehouse management. The software is available in English, German, French, Chinese and Italian. Tecnomatix Plant Simulation is a product of Siemens PLM Software.

Advantages of using Simulation software for manufacturing plant design

When designing a manufacturing plant, engineers must take into account a wide variety of factors, from the factory floor plan to the specific needs of the production process.

The goal is to create a design that is both efficient and effective, reducing waste and maximizing output. Simulation software is a tool that can be used to test different designs and find the most successful solution.

By entering plant data and measurements into the software, objects and resources, logistics constraints, and existing systems and products, engineers can visualize how different layouts impact production. This allows for an efficient and complete design process and a higher quality final deliverable.

Use Plant Simulation to optimize output performance

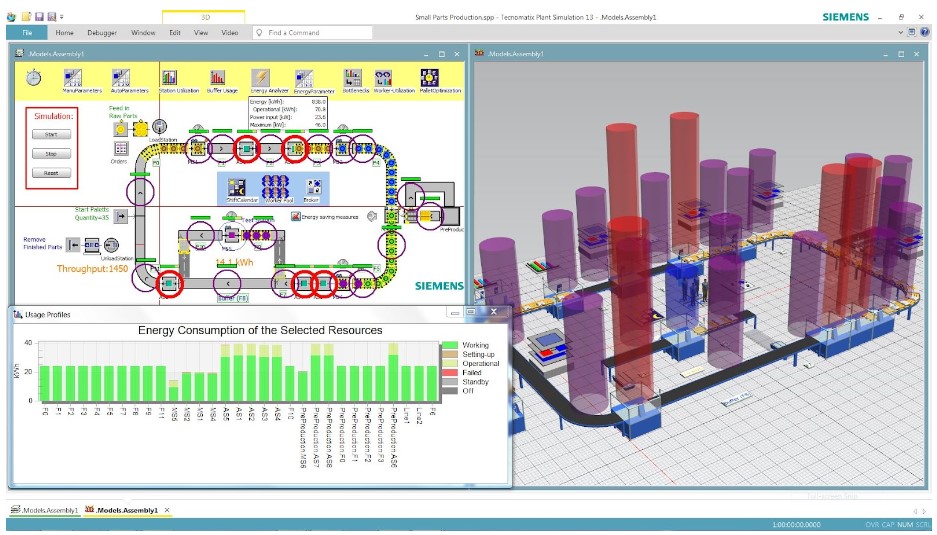

Siemens Plant Simulation is a powerful tool to generate alternatives and solutions on how to optimize production output performance with fewer resources and energy.

By creating simulations of different layouts and production processes, it is possible to identify bottlenecks and inefficiencies.

Through trial and error, it is possible to find the best configuration for a given plant. Additionally, Plant Simulation can be used to train a user in how to operate the equipment avoiding the need for evaluation, planning and training on the real equipment, reducing risks and efforts. This way you can reduce stops and maximize productivity.

How Siemens Plant Simulation Eliminates Bottlenecks

The software is designed to help identify bottlenecks in manufacturing processes. It allows users to create virtual models of their production lines and test different scenarios to see the effect they can have on line performance.

This helps determine potential improvements that can be made to the actual production process, increasing efficiency and output. It also allows measuring the impact of the proposed changes on other aspects of the production line such as materials handling or use of machinery.

Descar Tech Services

Siemens Plant Simulation is an essential tool for optimizing your manufacturing operations.

The system allows you to simulate industrial plants before they are built, saving time and money

The system is accurate and reliable, ensuring that its simulations are as close to reality as possible.

Contact us today for more information on sales, installation and configuration of PLANT SIMULATION.

Recent Comments